INTRODUCTION

India is the second largest producer of cement in the world. It accounts for more than 7% of the global installed capacity. India has a lot of potential for development in the infrastructure and construction sector and the cement sector is expected to largely benefit from it. Some of the recent initiatives, such as development of 98 smart cities, is expected to provide a major boost to the sector.

Aided by suitable Government foreign policies, several foreign players such as Lafarge-Holcim, Heidelberg Cement, and Vicat have invested in the country in the recent past. A significant factor which aids the growth of this sector is the ready availability of raw materials for making cement, such as limestone and coal.

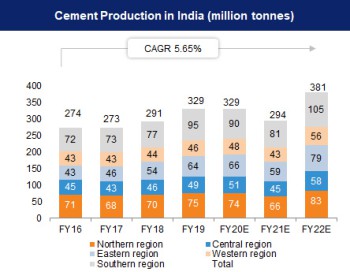

India’s overall cement production accounted for 294.4 million tonnes (MT) in FY21 and 329 million tonnes (MT) in FY20.

MARKET SIZE

Cement production reached 329 million tonnes (MT) in FY20 and is projected to reach 381 MT by FY22. However, the consumption stood at 327 MT in FY20 and will reach 379 MT by FY22. The cement demand is estimated to touch 419.92 MT by FY 2027. As India has a high quantity and quality of limestone deposits through-out the country, the cement industry promises huge potential for growth.

As per ICRA, in FY22, the cement production in India is expected to increase by ~12% YoY, driven by rural housing demand and government’s strong focus on infrastructure development.

As per Crisil Ratings, the Indian cement industry is likely to add ~80 million tonnes (MT) capacity by FY24, the highest since the last 10 years, driven by increasing spending on housing and infrastructure activities.

Higher allocation for infrastructure – US$ 26.74 billion in roads and US$ 18.84 billion in railways in union budget of FY23, is likely to boost demand for cement.

According to CLSA (institutional brokerage and investment group), the Indian cement sector is witnessing improved demand. Key players reported by the company are ACC, Dalmia and Ultratech Cement. In the second quarter of FY21, Indian cement companies reported a sharp rebound in earnings and demand for the industry increased, driven by rural recovery. With the rural markets normalising, the demand outlook remained strong. For FY21, CLSA expects a 14% YoY increase in EBITDA in the cement market for its coverage stocks.

INVESTMENTS

As per DGCIS, India’s export of portland cement, aluminous cement, slag cement, supersulphate cement and similar hydraulic cements stood at US$ 118.15 million in FY21. FDI inflows in the industry, related to the manufacturing of cement and gypsum products, reached US$ 5.24 billion between April 2000-September 2021.

In 2021, working remotely is being adopted at a fast pace and demand for affordable houses with ticket size below Rs. 40-50 lakh (US$ 53,694-67,118) is expected to rise in Tier 2 and 3 cities, leading to an increase in demand of cement.

Private equity investments in real estate surged 24% YoY to US$ 477 million between July 2021 to September 2021.

Some of the major investments and development in Indian cement industry are as follows:

- In February 2022, ACC Limited, announced the successful commissioning of a 1.6 MTPA Grinding Unit (GU) at Tikaria in Uttar Pradesh.

- In November 2021, UltraTech Cement announced its commitment to the Global Cement and Concrete Association (GCCA) 2050 Cement and Concrete Industry Roadmap to produce carbon-neutral concrete by 2050.

- In November 2021, Dalmia Cement announced plans to produce 100% low carbon cement by 2031. The company has a US$ 405-million carbon capture and utilisation (CCU) investment plan to help it realise its goal.

- Dalmia Cement plans to spend US$ 1.35 billion to increase its installed cement capacity by 52% to 50MT/yr from 33MT/yr before the FY2024.

- In November 2021, Dalmia Cement announced plans to invest US$ 70.1 million for setting up its upcoming 2MT/yr cement plant in Bokaro, Jharkhand.

- In October 2021, JK Cement Ltd. signed a long-term strategic Memorandum of Understanding (MoU) with Punjab Renewable Energy Systems Private Limited (PRESPL). The MoU is part of JK Cement’s attempts to decarbonize its operations and significantly scale-up the use of biomass-based and alternate fuels as replacements to fossil fuels, like coal, in its manufacturing operations.

- In October 2021, JSW Group collaborated with Salesforce to support an ambitious digital strategy. Using Salesforce’s Sales Cloud and Service Cloud, JSW Group will offer a single group interface, enhancing distribution, customer experience and supply chain for the large project division across its steel and cement businesses.

- In October 2021, Hyderabad-based Penna Cement Industries, received approval from the capital markets regulator Securities and Exchange Board of India (SEBI), to go ahead with its Rs. 1,550 crore (US$ 206.75 million) initial public offering (IPO).

- In September 2021, Ambuja Cement launched ‘Concrete Futures Laboratory’, a one-stop solution that will enable budding professionals to test, learn and experience various aspects of cement and concrete.

- In September 2021, the Odisha government approved Ramco Cements expansion plan with an additional grinding capacity of 0.9 MTPA capacity at Haridaspur in Jajpur with an investment value of Rs.190 crore (US$ 25.5).

- In August 2021, Ramco Cement plans to invest additional Rs. 601.2 crore (US$ 80.8) to upgrade cement plants that will be completed by March 2022. In April 2021, the company had invested Rs. 401 crore (US$ 53.9) for upgrades.

- In August 2021, Dalmia Cement will invest Rs. 773.8 Crore (US$ 104 million) to expand its cement operations in Jharkhand.

- In August 2021, UltraTech Cement announced plans to increase cement capacity by 19.8 MTPA between 2022 and 2023. Upon completion of the project, which is valued at Rs. 6,510 crore (US$ 875 million), the capacity would rise to 136.3 MTPA.

- In September 2021, Shree Cement launched three projects that were valued at Rs. 4,806 crore (US$ 646 million). Of this, Rs. 3,541 crore (US$ 476 million) will be used to establish 3.8 MTPA cement plant in Rajasthan, while the remaining amount will be spent on establishing a grinding plant in West Bengal and installing solar power plants at various cement plants across the country that are valued at Rs. 759 crore (US$ 102 million) and Rs. 506 crore (US$ 68 million), respectively.

- In September 2021, Ambuja Cement introduced Concrete Futures Laboratories to test various aspects of cement and concrete.

- In August 2021, Ambuja Cement announced to invest Rs. 310 crore (US$ 41.82 million) to expand its manufacturing capacity in Ropar Unit, Punjab and cater to the rising demand from manufacturing sector for housing construction and public infrastructure development. The expansion activities are expected to be completed by June 2023.

- In July 2021, Ramco Cements launched Ramco Super Plaster, a plastering solution for brick work and plastering applications.

- In July 2021, Vedanta announced that its aluminium unit invited bids for alliances from cement manufacturing companies such as JK Cement, ACC and UltraTech Cement to utilise fly ash, a by-product, to produce low-carbon cement.

- In July 2021, Ramco Cements announced its plan to invest US$ 64 million in capacity expansion and modernisation activities of its plant unit in Tamil Nadu.

- In July 2021, Dalmia Bharat Ltd. announced its plan to raise the company’s production capacity to 110-130 million tonnes per annum by 2031.

- In July 2021, JSW Cement signed an agreement with Synergy Metals Investments Holding Ltd. and Apollo Global Management Inc. to raise investment funds worth Rs. 1,500 crore (US$ 202.35 million) and expand its production capacity to 25 million tonnes from 14 million tonnes.

- In June 2021, Ambuja Cements and ACC announced to invest in Industry 4.0 under its ‘Plants of Tomorrow’ programme, which aims to boost cement manufacturing through enhanced plant optimisation, improved plant availability and a safer operational environment.

- In June 2021, Ramco Cements Limited commissioned the Line III of its Jayanthipuram Plant, with a clinker manufacturing capacity of 1.50 million tonnes per annum.

- In June 2021, JSW Cement entered construction chemical business with the introduction of an exclusive green product range.

GOVERNMENT INITIATIVES

In order to help private sector companies, thrive in the industry, the Government has been approving their investment schemes. Some of the initiatives taken by the Government off late are as below:

- In October 2021, Prime Minister, Mr. Narendra Modi, launched the ‘PM Gati Shakti - National Master Plan (NMP)’ for multimodal connectivity. Gati Shakti will bring synergy to create a world-class, seamless multimodal transport network in India. This will boost the demand for cement in the future.

- In July 2021, the government established a council of 25 members (comprising UltraTech Cement MD Mr. K C Jhanwar, Dalmia Bharat Group CMD Mr. Puneet Dalmia) for the cement industry to reduce waste, achieve maximum production, enhance quality, reduce costs and encourage standardisation of products.

- Under the housing for all segment, 8 million households will be identified according to the Budget 2022-23 with Rs. 48,000 crore (US$ 6.44 billion) set aside for PM Awas Yojana.

- As per the Union Budget 2022-23, the government approved an outlay of Rs. 1,99,107 crore (US$ 26.74 billion) for the Ministry of Road Transport and Highways, and this step is likely to boost the demand for cement.

- As per Invest India, National Infrastructure Pipeline (NIP) expanded to 9,305 projects from 7,400 projects.

- The Union Budget allocated Rs. 13,750 crore (US$ 1.88 billion) and Rs. 12,294 crore (US$ 1.68 billion) for Urban Rejuvenation Mission: AMRUT and Smart Cities Mission and Swachh Bharat Mission.

ROAD AHEAD

The eastern states of India are likely to be the newer and untapped markets for cement companies and could contribute to their bottom line in future. In the next 10 years, India could become the main exporter of clinker and gray cement to the Middle East, Africa, and other developing nations of the world. Cement plants near the ports, for instance the plants in Gujarat and Visakhapatnam, will have an added advantage for export and will logistically be well armed to face stiff competition from cement plants in the interior of the country. India’s cement production capacity is expected to reach 550 MT by 2025.

Due to the increasing demand in various sectors such as housing, commercial construction and industrial construction, cement industry is expected to reach 419.92 million tonnes per annum (MTPA) by the FY 2027.

A number of foreign players are also expected to enter the cement sector owing to the profit margins and steady demand.

Note:Conversion rate used for November 2021 is Rs. 1 = US$ 0.01336

References:Media Reports, Press releases, Union Budget 2019-20, Edelweiss Securities Ltd.

Disclaimer:This information has been collected through secondary research and IBEF is not responsible for any errors in the same.

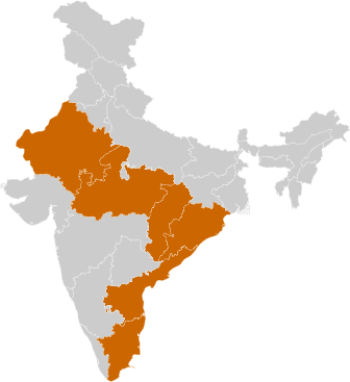

Cement Clusters

- Rajasthan

- Tamil Nadu

- Andhra Pradesh

- Madhya Pradesh

- Chhattisgarh

- Odisha

Industry Contacts

- Indian Concrete Institute

- National Council for Cement and Building Materials

- Cement Manufacturers' Association (CMA)